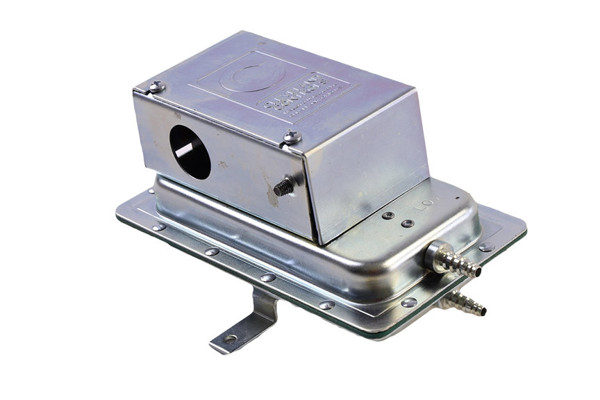

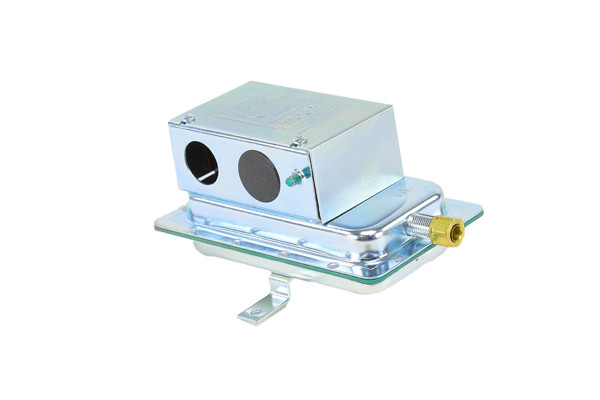

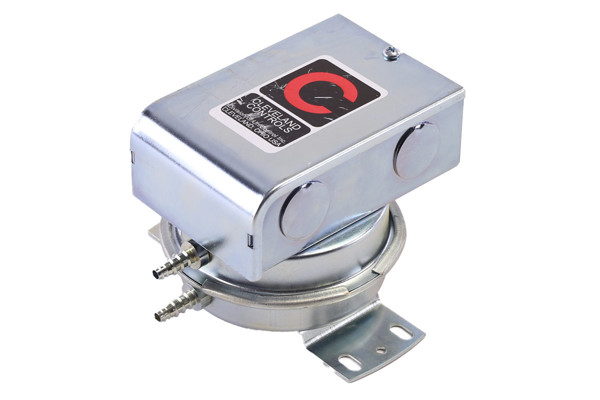

Air Pressure Switches

Air pressure switches can be used in many different applications. For boilers and burners, most of them prove proper air flow through the combustion chamber and/or exhaust flue. BoilerWAREhouse stocks many different air pressure switches: differential, vacuum and pressure for commercial and industrial boilers.

If you do not see the part you want below, feel free to use the chat function and see if we possibly have the part you are looking for in stock.

Most Popular

-

Honeywell

High Pressure Switch 1" - 20" W.C. Manual Reset

- SKU:

- C6097B3028

- In Stock:

- 623 available

What are Air Pressure Switches & What is their function?

Air pressure switches confirm proper flow

In order to do its job, a boiler’s furnace needs air coming in, and it needs to vent the byproducts of combustion. Air pressure switches monitor the pressures along the way to make sure the furnace has what it needs when it needs it, and that all exhaust gasses are safely vented.

Air pressure switches measure pressure for safety and performance

The combustion cycle of a boiler’s furnace is actually one long continuous path that starts when fresh air enters the boiler’s intake and ends when the exhaust gasses meet the atmosphere. That path has to flow in the same direction at all times to preserve safety through ventilation and steam production.

Air pressure switches measure the pressure at the intake and at the exhaust flue to make sure that combustion is occurring as it should, creating a positive draft.

Depending on their location in the combustion path, air pressure switches may be designed to measure positive pressure, vacuum, or pressure differential across two areas.

The Role Air Pressure Switches Play in a Boiler

Without air pressure switches, a boiler operator would have no idea how much air was being fed to the boiler’s furnace, or if all of the exhaust was venting properly up the stack. This could make the furnace run too rich or too lean, or create a dangerous backup of exhaust gasses.

What are the Effects of a Bad Air Pressure Switch?

If an air pressure switch is starting to fail, it will give incorrect readings that will cause the furnace to get too much or too little air. If it’s located in the stack, it will show too much or too little exhaust pressure. This will cause a change in the steam capacity and fuel consumption of the boiler.

Things to Consider about air pressure switches:

- Pressure can be measured in several different units including pounds per square inch and millibars.

- If you’re installing a new pressure switch, make sure it’s calibrated properly, and that it’s sending pressure readings in the same units your control system uses.

Helpful Resources

Relevant WARE Videos on Air Pressure Switches

Checking the Makeup Air in the Boiler Room

Sizing The Blower Motor for an Industrial Boiler

What is an Atmospheric Boiler?

History of The Portable Steam Boiler

Explore over 750+ explanatory videos on boilers and boiler systems on our Youtube channel. Our videos can help you quickly grasp complex boiler topics. Watch more here!

Relevant WARE Blog Articles on Air Pressure Switches

Different Types of Air Pressure Switches

Understanding Boiler Pressure Controls

Today’s Lesson in Physics: The relationship between steam pressure and temperature

Our informative and educational blog content can help you gain a deeper understanding of the boiler room. Read more here!

Technical Documents

Air Pressure Switch FAQ

How does an air pressure switch work?

Air pressure switches can use a variety of methods to measure pressure. Some use diaphragms or spring-tensioned pistons that move as the pressure on them increases or decreases, while others use electronic sensors.

What’s the difference between a set point and a cut point?

The “set point” is the specific pressure reading at which a switch will activate. By contrast, the “cut point” is the pressure reading at which the switch will turn off.