Pumps

Most boiler rooms will have at least one pump if not more. Pumps are essential to moving feed water into the boiler but they can be also used in different applications. They can come in several different versions such as base mounted or close coupled.

If you do not see the part you want below, feel free to use the chat function and see if we possibly have the part you are looking for in stock.

Pumps Categories

Manufacturers View all

What is a Pump & What is its function?

Pumps are used to maintain a consistent supply of feedwater to your boiler. As the steam returns from its process, it condenses back into liquid water. That water must be returned to the boiler to keep the steam cycle going, which is accomplished by the use of one or more feedwater pumps.

Pumps Keep The Water Coming

Every boiler operates under pressure. Consequently, feedwater must be forced into the boiler at a pressure greater than that inside the vessel. That’s where pumps come in. They make sure the feedwater can enter the boiler as needed, even at high temperatures and pressures.

Different Types of Pumps & How to Choose

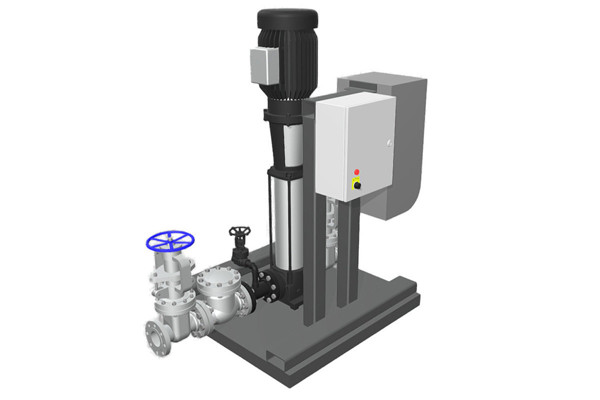

WARE sells two main kinds of pumps: Close-coupled and base-mounted. Both are centrifugal pumps, meaning they use impellers or rotors to spin the water inside a circular housing until it’s under enough pressure to move where it needs to go.

Base-mounted pumps are all-in-one units that contain every moving part connected on one base. The motor, pump, bearings, and all other components are assembled at the factory, and installed together in one ready-to-go package.

Close-coupled pumps are divided into two main components, the pump housing and the motor. The pump and motor are connected by a shaft that actuates the pump as the motor turns. Close-coupled pumps are installed in two pieces, either of which may be swapped out as needed for maintenance, repair, or replacement.

The Role Pumps Play in a Boiler

Gravity alone isn’t enough to keep the water flowing where it needs to go. Feedwater must be supplied under pressure, or it will not be able to enter the boiler. Pumps keep the feedwater at the necessary pressure to be able to enter the boiler as needed.

What is the Effect of a Bad Pump?

If a water pump fails, the boiler will not have enough feedwater supplying it to replace the water that’s been converted to steam. Consequently, the boiler’s water level will drop. This is a dangerous situation that can drastically reduce the life of your boiler, and create a safety hazard.

Things to Consider About Pumps:

- Close-coupled pumps are designed to be easier to service and repair, because each main component can be removed by itself.

- Close-coupled pumps are better suited to lower temperatures and pressures, because they have more external seals than base-mounted pumps.

- Base-mounted pumps are sturdier and more resistant to high temperatures and pressures, because they are more self-contained and require fewer seals.

Helpful Resources

Relevant WARE Videos on Pumps

What is Pump Cavitation in Boiler Feed Water?

What Are Feed Pump Recirculation Lines

Steam Powered Water Pump Part 2

Largest Steam Powered Pump in the World

What is the Crossness Pumping Station

Checking the Strainer On the Feed Water Pump Inlet

Explore over 750+ explanatory videos on boilers and boiler systems on our Youtube channel. Our videos can help you quickly grasp complex boiler topics. Watch more here!

Relevant WARE Blog Articles on Pumps

The Pressure Is On: Pumps in a Boiler System

What Are Feed Pump Recirculation Lines?

Having Issues with Your System? Check These Common Boiler Issues First

Modulating Feedwater Valves: The Method Behind the Movement

Our informative and educational blog content can help you gain a deeper understanding of the boiler room. Read more here!

Technical Documents

Pump FAQ

What do axial and radial flow mean?

Axial-flow pumps move water along the same axis as the impeller or rotor, so the water flows in the same axis as the pump shaft.

Radial-flow pumps move water using an impeller or rotor that is perpendicular to the axis of the shaft motor. ‘

What’s the difference between a centrifugal pump and a positive displacement pump?

Centrifugal pumps use a rotating disk or impeller that spins in a circular housing, pushing the water to the outside of the housing under pressure.

Positive-displacement pumps, on the other hand, move a specified quantity of water by pushing or pulling it using suction.

What’s the difference between a rotary pump and a reciprocating pump?

A rotary pump operates much like a screw or auger, constantly turning along the axis of water flow inside a housing to push the water along.

Reciprocating pumps operate more like a bicycle pump, pushing or pulling the water in cycles as the piston moves back and forth.