Burner Diffusers

The burner diffusers create the needed turbulence in the fuel and air to achieve optimal combustion. This is essential to having a proper flame in the boiler. These diffusers will be specific to the make and model of the boiler. BoilerWAREhouse has diffusers for Cleaver-Brooks, Limpsfield, and more.

If you do not see the part you want below, feel free to use the chat function and see if we possibly have the part you are looking for in stock.

Burner Diffusers Categories

Manufacturers View all

Cleaver-Brooks parts: WARE is not an authorized sales representative of Cleaver-Brooks, Inc. or related to Cleaver-Brooks in any way, nor does WARE provide or manufacture any genuine, authorized or OEM Cleaver-Brooks replacement parts. Any aftermarket replacement parts for boilers sold or provided by WARE are manufactured by or on behalf of Ware and not Cleaver-Brooks. Cleaver-Brooks® is a registered trademark owned by Cleaver-Brooks, Inc.

What are Burner Diffusers & what is their function?

Burner diffusers mix air and fuel for efficient combustion

The fuel coming into a boiler’s furnace needs to mix with oxygen before it can burn. Burner diffusers mix the fuel and oxygen together while creating turbulence that lets the oxygen and fuel mix more thoroughly before ignition.

Burner diffusers keep the heat even

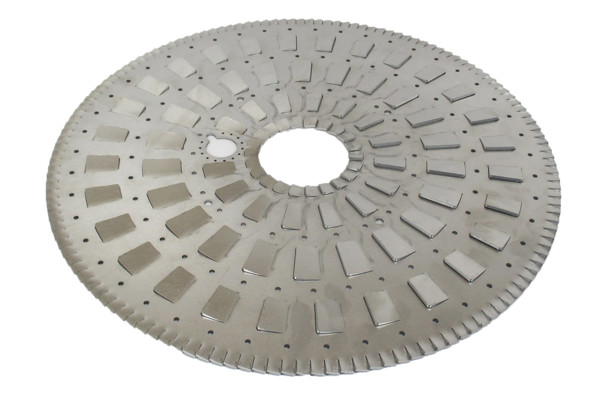

Every burner diffuser is designed with specific channels and pathways through which the fuel and oxygen flow to create a specific mixture for combustion. Burner diffusers are each designed to work with a specific make and model of boiler, shaping and spreading the flame to evenly cover the tank surface without hot spots that can shorten a boiler’s life.

Different Types of Burner Diffusers & How To Choose

WARE carries burner diffusers for nearly any make and model of boiler, but our warehouse primarily stocks two main types.

CB Series Diffusers

LC Series Diffusers

The Role Burner Diffusers Play in a Boiler

The way fuel and oxygen are combined before ignition determines how well they will burn. Proper mixing saves fuel costs by burning the fuel as efficiently as possible, while also reducing the number of combustion byproducts and excess oxygen that flow into the stack.

what are the Effects of a Bad Burner Diffuser?

If a burner diffuser is starting to fail, it may not mix the fuel and oxygen properly. This can create a low flame or a flame that is too rich or too lean. That can cause uneven heating and premature boiler wear while allowing excess combustion byproducts and corrosive oxygen into your stack.

Things to Consider about burner diffusers:

- Regular cleaning of your burner’s furnace will help your burner diffusers do their job.

- Make sure your burner diffusers are properly inspected and adjusted (tuned) by a professional on a regular basis.

- Monitor your stack exhaust and fuel flow rates to make sure your burners are performing properly.

Helpful Resources

Relevant WARE Videos on Burner Diffusers

How Diffusion Burners & Premix Burners Work

Inside a Watertube Rental Boiler

Looking at the Main Flame in the Boiler

Explore over 750+ explanatory videos on boilers and boiler systems on our Youtube channel. Our videos can help you quickly grasp complex boiler topics. Watch more here!

Relevant WARE Blog Articles on Burner Diffusers

The Heat Hero: Burner Diffusers

Cleaning the Burner's Flame Sensor

A Quick Scan of Flame Scanners

Our informative and educational blog content can help you gain a deeper understanding of the boiler room. Read more here!

Technical Documents

Burner Diffusers FAQ

How important is an exact replacement for a burner diffuser?

Absolutely critical. Every boiler’s burner diffusers are designed in a specific way for a specific reason, to work with that specific boiler. Substituting other burner diffuser designs can be extremely dangerous, or at the very least shorten your boiler’s life.

What’s the difference between a diffusion burner and a premix burner?

Premix burners draw a supply of fuel and oxygen from a manifold, mixing them before pushing them through a metal mesh for combustion. In a premix burner, the flame essentially “floats” on the other side of the metal mesh without traveling inside to cause an explosion.

Diffusion burners mix the oxygen and fuel by injecting them through nozzles or outlets into a spinning fan or impeller before combustion.