Gas Regulators

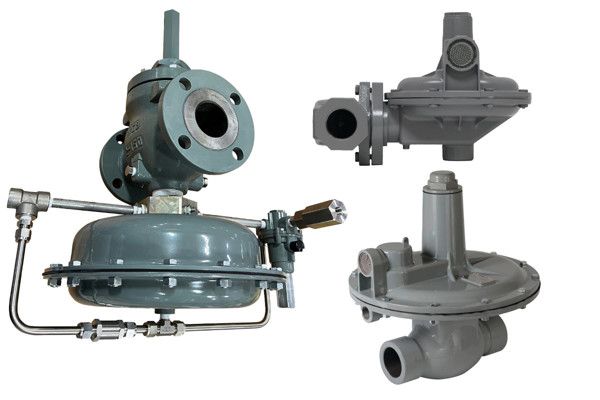

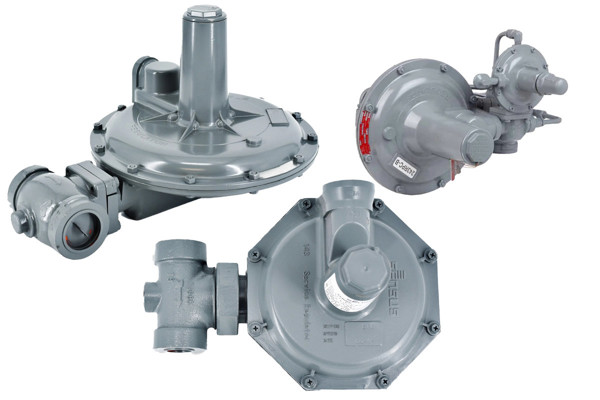

Gas regulators are the critical safety component that step down high incoming utility pressure to the safe, stable operating pressure required by your commercial and industrial equipment. Properly sized based on your inlet pressure, outlet pressure, and the specific flow rate needed to reliably operate your burners and appliances, these units ensure efficiency and compliance. Shop leading brands including Maxitrol, Belgas, and Sensus for reliable gas control

If you do not see the part you want below, feel free to use the chat function and see if we possibly have the part you are looking for in stock.

Gas Regulators Categories

Manufacturers View all

What Are Gas Regulators & What Is Their Function?

Gas regulators maintain proper gas pressure

The gas coming in from the utility supply line is often at too high a pressure to allow the boiler to operate safely. Installing a gas regulator in the boiler’s gas train will make sure the pressure is stepped down to a usable level before it reaches the boiler’s furnace.

Gas regulators preserve efficiency and safety

The gas flowing in from a utility has to be kept at high pressure because it has to supply other equipment in addition to the boiler. If the pressure doesn’t drop before it reaches the burner, it can cause a range of problems.

The Role Gas Regulators Play In A Boiler

If the incoming gas is at too high a pressure when it reaches the burner, it can cause damage to the burner itself, requiring recalibration or even replacement. High gas pressure will also increase the size of the flame itself, causing heat stress in the boiler tank that can lead to cracks, leaks, and explosions. Even if it doesn’t cause immediate or obvious damage, high gas pressure will still cause fuel consumption to go up, reducing efficiency.

What Are The Effects Of A Bad Gas Regulator?

If a gas regulator goes bad, the supply pressure to the burners will either become too high or too low. If the pressure is too high, it will affect efficiency, safety, and boiler integrity. If the pressure is too low, the burner may go out, or the boiler may not produce sufficient steam.

Things To Consider About Gas Regulators:

- Gas regulators are rated for specific conditions, so be sure you always choose the right regulator for the job.

- They are sized based on inlet pressure, outlet pressure, and required flow rate.

Helpful Resources

Relevant WARE Videos on Gas Regulators

Gas Pressure Regulation Station

Gas Pressure Regulation for Boiler Combustion

How To Check the Pilot Gas Pressure

Reading Gas Pressure Gauges on Gas Train

Checking Gas Train for Leaks on a Steam Boiler

NFPA 85 Code: Gas Train and Venting

Getting the Right Gas Pressure to the Burner for Combustion

Explaining Natural Gas Curtailment

Inspecting a Honeywell Gas Valve Actuator For Leaking Fluid

Using a Vent Orifice on a Siemens Gas Regulating Actuator

Gain Efficiency Using Turbulators in a Boiler

Parts of the Boiler Room | Boiler Combustion and Steam System

Boiler Combustion Tuning and Analysis

Combustion Series Part 1: Regulators

Explore over 750+ explanatory videos on boilers and boiler systems on our Youtube channel. Our videos can help you quickly grasp complex boiler topics. Watch more here!

Relevant WARE Blog Articles on Gas Regulators

What the Heck is Liquid Natural Gas?

NFPA 85 Code: Gas Train and Venting

Our informative and educational blog content can help you gain a deeper understanding of the boiler room. Read more here!

Technical Documents

Gas Regulators FAQ

How does a gas regulator work?

A gas regulator is a device that reduces high-pressure gas from a cylinder or pipeline to a safe, steady pressure for appliances or industrial systems. It works by using a spring-loaded diaphragm and a valve to automatically adjust the flow: when outlet pressure drops, the valve opens to allow more gas in; when pressure rises, the valve closes slightly to maintain balance. This ensures consistent gas delivery, prevents dangerous overpressure, and protects equipment. Regulators are essential for applications like boilers and industrial burners, and HVAC systems, providing both safety and efficiency in gas-powered systems.

How is the pressure adjusted in a gas regulator?

Gas regulators are adjusted using a control knob or set screw that changes the tension on the main spring. This spring tension directly controls the position of the diaphragm; less tension requires less downstream gas pressure to push the diaphragm back and close the valve, thus lowering the outlet pressure.

How often should a gas regulator be replaced?

Because they use simple moving parts and physics, gas regulators tend to last a long time. However, the components begin to wear out even under ideal conditions. For safety’s sake, it’s best to have your regulator inspected regularly, and replaced at least once every ten years.